Industrial robots and cobots (collaborative robots) are playing an increasingly important role in the automation of manufacturing processes in industrial settings. Using this technology can help companies to increase their productivity and efficiency, improve the quality of their products and to relief their employees at work.

However, with new application scenarios and applications new challenges are involved. To meet these demands, we work closely with leading robot manufacturers. By bundling know-how, it allows us to offer a wide range of end-of-arm solutions tailored to the specific requirements of your applications.

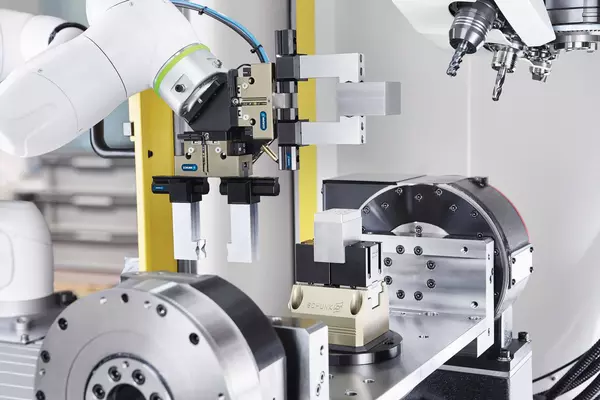

Machine loading becomes child's play with cobots, for example in conjunction with the Universal gripper EGU . In perfect coordination, they reliably support people during repetitive and monotonous work steps. This creates greater freedom for employees to be deployed for more demanding tasks. Cobots can be easily integrated into the loading and unloading process, and therefore present a big step forward n creating a smart production environment.

Advantages:

Our MTB application kits are well suited for machine loading and unloading. They seamlessly fit into the machine environment, taking on the important key role of workpiece handling and workpiece clamping. Due to the integrated blow-off nozzle, robust design, and sealed electronics, the MTB application kits are highly application-specific and perfectly suited for use in harsh and dirty environments.

Handling includes any kind of handling of workpieces, such as transportation, sorting or reorientation of parts within the logistical sequences of a production. In automated processes, these sequences are essential to prepare the workpieces for the next work step. Depending on the process, high requirements are placed on the flexibility of the handling components.

The mechatronically operated gripper is suitable for handling especially sensitive components in the electronics industry. Gripper for small components EGK .

Advantages:

Assembly applications include the process of assembling and joining multiple workpieces. Precise and reproducible handling is crucial here. Often, different tools are used to successively perform several assembly processes. Components for testing forces and torques can be used to ensure a correct joining process.

Advantages:

Quality inspection and quality assurance serve to ensure product quality during production. Depending on the workpieces and processes, various testing and measuring procedures can be automated. Handling components and Force/torque sensors enable automated quality inspection and support documentation of measuring and inspection values.

Advantages:

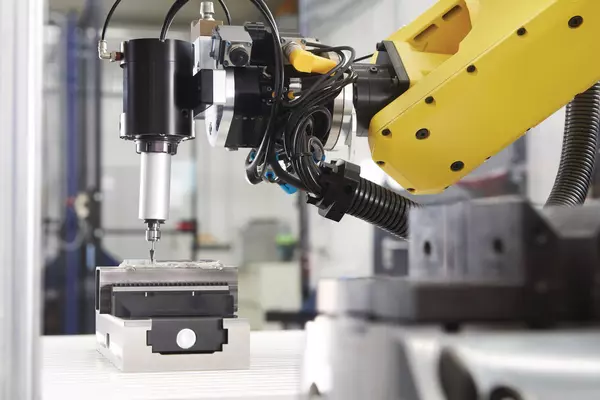

SCHUNK tools can be used to automate a large number of machining steps, such as deburring, grinding and polishing. These steps were previously manually performed. Automation can minimize risks and create added value at the same time.

Advantages:

Interacting intelligently and safely with humans. SCHUNK sets benchmarks – also in human-robot collaboration (HRC). As a pioneer, SCHUNK introduced the Co-act EGP-C , the first certified industrial gripper for collaborative operation on the market.